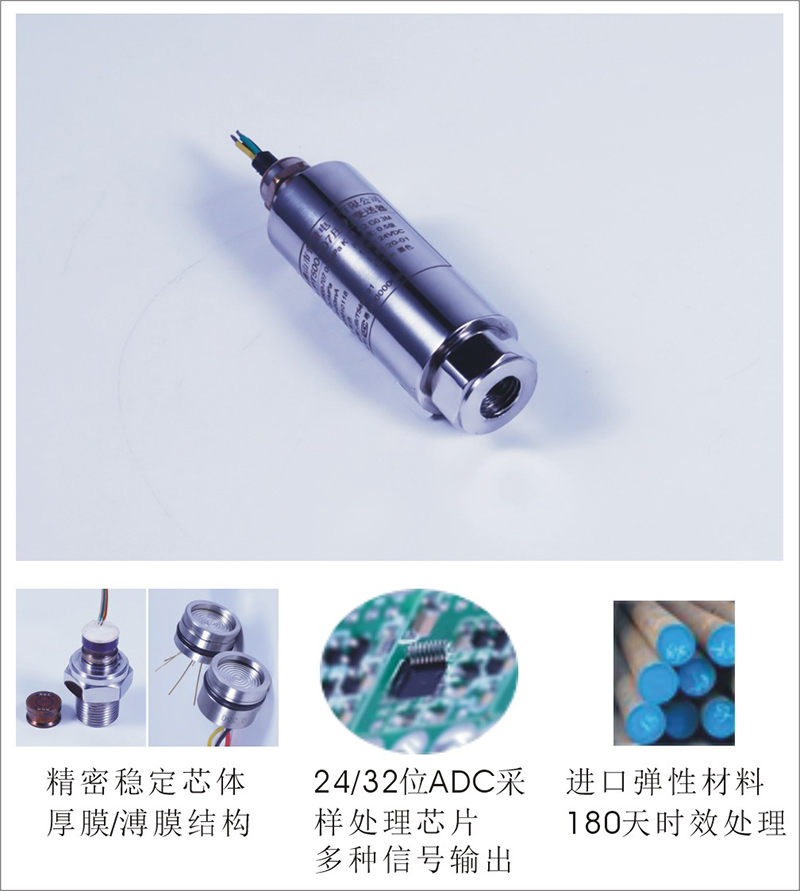

型號:PT500-707

精密穩(wěn)定壓力芯體�;

冷媒介質(zhì)(空調(diào)、冷庫等)過程連接結(jié)構(gòu)設(shè)計���;

不銹鋼過程連接,7/16-20NUF標(biāo)準(zhǔn)螺紋���;

抗疲勞、耐沖擊���、良好的重復(fù)性能�;

可替代同類型國外產(chǎn)品���;

常用關(guān)鍵字:

冷媒壓力變送器 冷媒壓力傳感器

空調(diào)壓力變送器 空調(diào)壓力傳感器

Model: PT500-707

Precision stable pressure core body;

Process connection structure design of refrigerant medium (air conditioning, cold storage, etc.);

Stainless steel process connection, 7 / 16-20nuf standard thread;

Fatigue resistance, impact resistance and good repeatability;

It can replace the same type of foreign products;

Common keywords:

Refrigerant pressure transmitter refrigerant pressure sensor

Air conditioning pressure transmitter air conditioning pressure sensor

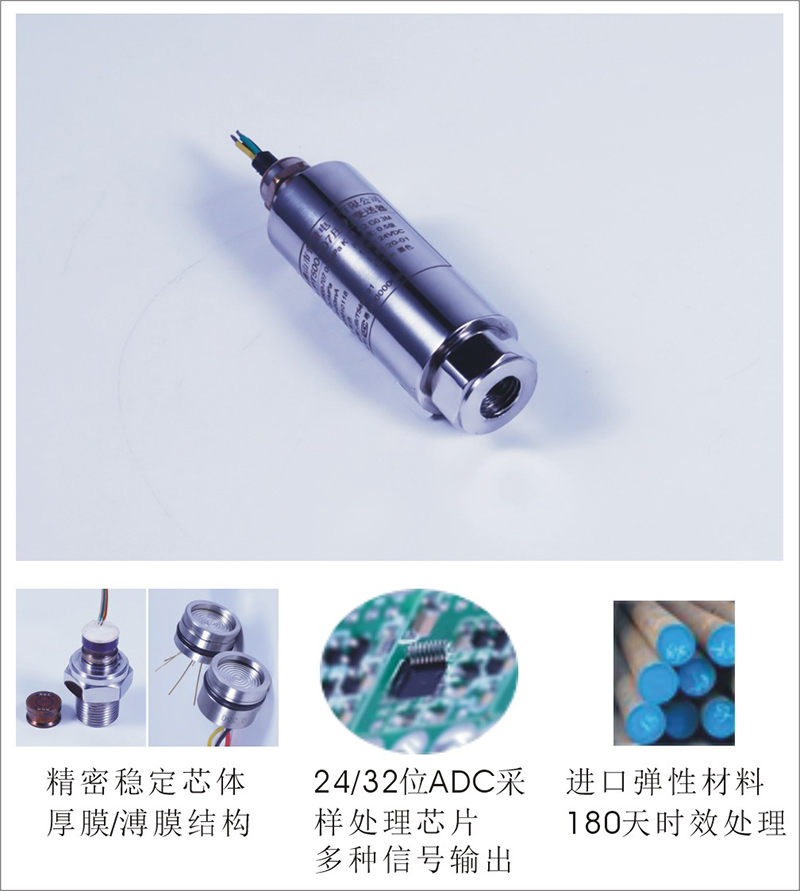

芯 片:

采用精密穩(wěn)定感壓芯片��;選進(jìn)的貼片工藝�����;

小量程芯片:充油硅芯片����;

大量程芯片:壓阻式厚膜芯片;

零點����、滿度,溫補(bǔ)�����、線性補(bǔ)償�����;

高阻抗���、高精度、高穩(wěn)定性�����;

100萬次使用壽命以上;

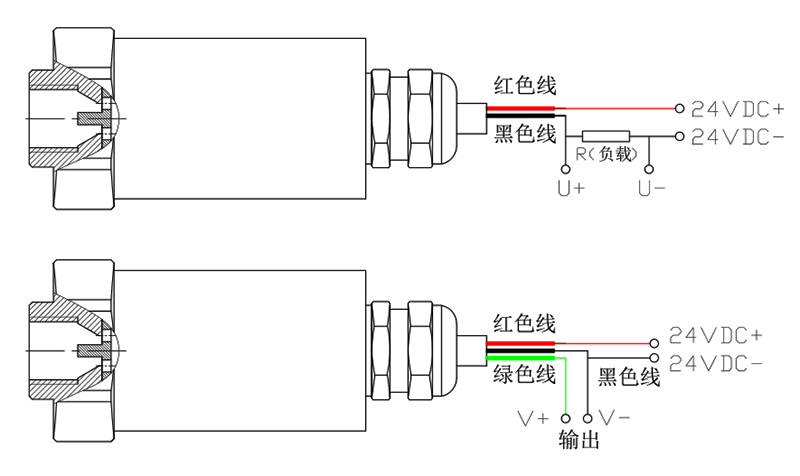

信號處理及輸出:

24位ADC采樣處理芯片���;

DSP數(shù)字信號調(diào)理算法����;

多點性線溫度校準(zhǔn)����;

電壓電流過載保護(hù);

標(biāo)準(zhǔn)工業(yè)信號輸出:4-20mA(二線制)����,0-20mA(三線制),0-5VDC���,0-10VDC��,0.5-4.5VDC(三線制);

數(shù)字通訊信號輸出:RS485-RTU���、超低功耗RS485-RTU

采用先進(jìn)的32bit微處理器和24bit ADC

傳輸協(xié)議采用通用的MODBUS-RTU協(xié)議

支持波特率:1200~57600bps,校驗位:NONE��、ODD����、EVEN

支持用戶二次校準(zhǔn)����、清零����、反清零、恢復(fù)出廠等操作

支持11種單位切換���,支持浮點型���、整型、百分比��、格式化輸出

采集間隔0~43200秒(12小時)可設(shè)�,既可連續(xù)采集,滿足高速采集的場合�,也可單次觸發(fā)采集,最大限度降低功耗

數(shù)字通訊信號輸出:Can2.0B

測量速率:10...1000Hz 可設(shè)置�����,默認(rèn) 50Hz

CANopen輸出內(nèi)置 完整的 CANopen 協(xié)議棧��,符合 DS301��、DS404 規(guī)范���,支持 LSS 服務(wù)�����,支持 BootLoader 在線 升級�����;

支持波特率(kbps)20/50/100/125/250(默認(rèn))/500/800/1000��;支持特性 NMT/Heartbeat/SDO/PDO/LSS/Bootloader����;CANopen 協(xié)議?���?梢愿鶕?jù)用戶的要求進(jìn)行定制;

J1939輸出內(nèi)置 J1939 協(xié)議棧�����,可以自由配置 PGN、SPN 以及 NAME�����,支持 BootLoader 在線升級����;支持波特率(kbps)20/50/100/125/250(默認(rèn))/500/800/1000;支持特性PGN��、SPN�、NAME等自由配置,J1939 協(xié)議?�?梢愿鶕?jù)用戶的要求進(jìn)行定制����;

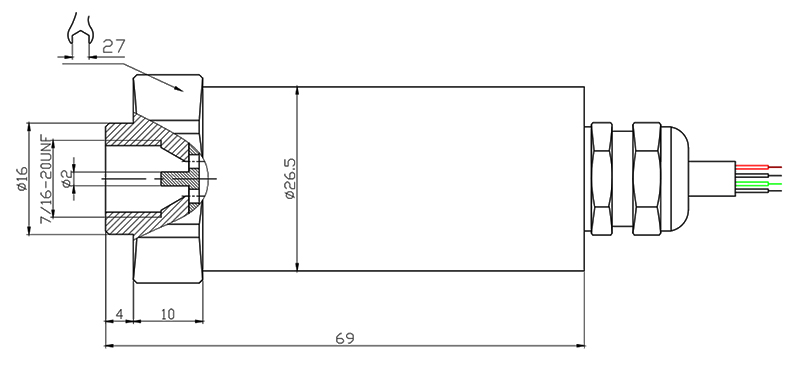

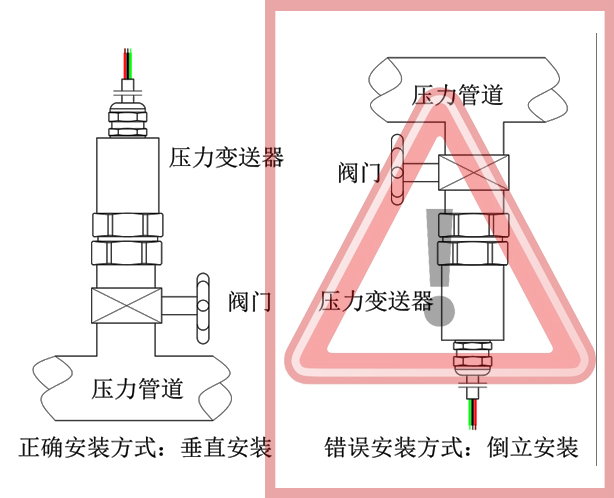

結(jié) 構(gòu):

深度氬弧焊接,連接彈性材料與過程接頭�,強(qiáng)度高,抗沖擊�,耐疲勞;

冷媒介質(zhì)(空調(diào)�、冷庫等)過程連接結(jié)構(gòu)設(shè)計;

不銹鋼過程連接,7/16-20NUF標(biāo)準(zhǔn)螺紋�;

抗疲勞��、耐沖擊�����、良好的重復(fù)性能;

過程連接材料:304或316���;

應(yīng) 用:

空調(diào)�����、冷庫等冷媒介質(zhì)的壓力測量與控制��;

樓宇/工業(yè)/電力/石油/自動化等領(lǐng)域的設(shè)備壓力測量���;

Chip:

It adopts precision stable pressure sensitive chip and selective placement technology;

Small range chip: oil filled silicon chip;

Large range chip: piezoresistive thick film chip;

Zero point, fullness, temperature compensation and linear compensation;

High impedance, high precision and high stability;

More than 1 million times of service life;

Signal processing and output:

24 bit ADC sampling and processing chip;

DSP digital signal conditioning algorithm;

Multipoint linear temperature calibration;

Voltage and current overload protection;

Standard industrial signal output: 4-20mA (two-wire system), 0-20mA (three wire system), 0-5vdc, 0-10vdc, 0.5-4.5vdc (three wire system);

Digital communication signal output: rs485-rtu, ultra-low power rs485-rtu

Advanced 32 bit microprocessor and 24 bit ADC are adopted

The transmission protocol is MODBUS-RTU

Support baud rate: 1200 ~ 57600bps, check bits: none, odd, even

Support the user's secondary calibration, reset, anti reset, restore factory operations

Support 11 kinds of units switching, support floating point, integer, percentage, formatted output

The acquisition interval of 0 ~ 43200 seconds (12 hours) can be set, which can not only meet the needs of high-speed acquisition, but also trigger acquisition once to minimize power consumption

Digital communication signal output: CAN2.0B

Measurement rate: 10... 1000Hz can be set, the default is 50 Hz

CANopen output built-in complete CANopen protocol stack, in line with ds301, ds404 specifications, support LSS services, support bootloader online upgrade;

Support baud rate (kbps) 20 / 50 / 100 / 125 / 250 (default) / 500 / 800 / 1000; support features of NMT / heartbeat / SDO / PDO / LSS / bootloader; CANopen protocol stack can be customized according to user requirements;

J1939 output has built-in J1939 protocol stack. PGN, SPN and name can be configured freely, and bootloader online upgrade is supported;

Support baud rate (kbps) 20 / 50 / 100 / 125 / 250 (default) / 500 / 800 / 1000; support free configuration of features such as PGN, SPN and name

The J1939 protocol stack can be customized according to the user's requirements;

Structure:

Deep argon arc welding, connecting elastic material and process joint, high strength, impact resistance and fatigue resistance;

Process connection structure design of refrigerant medium (air conditioning, cold storage, etc.);

Stainless steel process connection, 7 / 16-20nuf standard thread;

Fatigue resistance, impact resistance and good repeatability;

Process connection material: 304 or 316;

Application:

Pressure measurement and control of air conditioning, cold storage and other refrigerant media;

Pressure measurement of equipment in building / industry / power / Petroleum / automation fields;